Thermal Imaging

Introduction

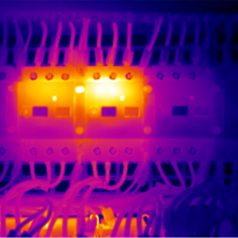

Thermal Imaging uses the infrared spectrum to see heat patterns and to measure temperatures. The relationship between radiation and temperature is complex in nature and needs the thermographer to understand the relationship between heat, temperature, type of material, reflection, emissivity and transmissivity.

Data that affects the accuracy of a thermal image include, ambient temperature, background temperature, relative humidity; distance from the object; wind, solar impact and load.

Not correctly understood it is possible for false conclusions to be reached, with significant cost implications. It needs to be remembered that an Infrared Camera is merely the tool, to help you understand what is happening. The information gained needs to be studied before conclusion can be reached.

Overview

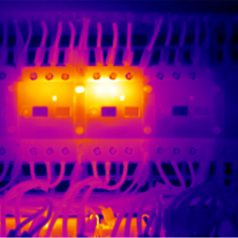

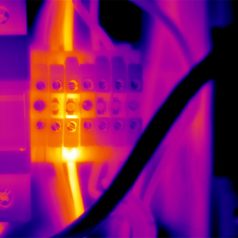

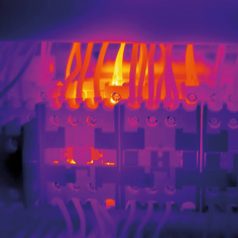

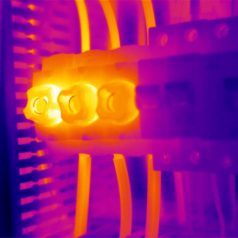

Infrared thermography can be used to in all major industries as a tool to help solve maintenance issues, improve safety and control maintenance costs by identifying issues before they become catastrophic. Typical inspections include building, mechanical and electrical. The thermal efficiency of building can be studied, and mechanical and electrical studies will identify heat patterns, allowing for heated related failures to be rectified.

It is also possible to identify moisture related damages by carefully determining heating and cooling patterns. It needs to be understood that this technology is one step in a process of many steps to get the full picture.

Technology & Terms

Technology

There are many different makes and models of cameras available. MRC Energy is of the firm opinion that in order to gain the best information possible, an infrared camera with a minimum resolution of 320 by 240 needs to be used. MRC Energy makes use of longwave uncooled camera’s.

Technical terms

Emissivity is the radiation that emanates from a surface. A shiny surface will give you the reading of the reflection of the ambient temperature, and not the actual object measured. A surface with a low emissivity value, such as aluminium and copper will return a low temperature reading, when affect the object or equipment being measured is actually very hot. It is the thermographers responsibility to understand this, and make sure the reference points being used will return an accurate measurement.

Another factor to affect temperature is the transmissive nature of the material. It is not possible to measure radiation through glass, and it is not possible to measure radiation through a metal plate. The thermographer needs to assess the best way to overcome these constraints.

It is also to understand the transfer of energy in terms of conduction, convection and thermal capacitance, as this will allow an accurate understanding of the causes of heat.

Electrical Inspections and Mechanical Inspections.

MRC Energy will be able to assist in all areas of inspections for mechanical and electrical related matters.

In order to gain a full understanding of the Power Quality of an installation, we will carry out thermal imaging to gain a holistic understanding of the electrical installation. It is common practice for only Distribution Boards to be thermally examined. MRC Energy will as part of the process study the mechanical parts and all electrical parts of an installation. This will allow the client to make informed decisions on the way forward.